Blueprinting, Photostating, and Allied Techniques

Contents

- Van Dyke and Lithoprint (First Costs High; Running Costs Low)

- Blueprinting and Photostating (First Costs Low; Running Costs High)

- Maximum Use of Area

- Prices per Square Foot

- Copying of Documents without a Camera

- Photostat

- Photocopying Equipment

- Dexigraph

- Technological Frontier

- Comparative Costs and Book Production

Word count: 8400

Van Dyke and Lithoprint (First Costs High; Running Costs Low)

∣

p.65

A number of techniques have been

developed for the copying of architects’

drawings, maps, and other non-textual material, but adapted to certain problems in

the reproduction of texts. In these copying techniques it is a question of decisive

importance whether the original from which

the copy is to be made is a positive or negative, and whether the copies are desired

in positive or negative form.

p.65

A number of techniques have been

developed for the copying of architects’

drawings, maps, and other non-textual material, but adapted to certain problems in

the reproduction of texts. In these copying techniques it is a question of decisive

importance whether the original from which

the copy is to be made is a positive or negative, and whether the copies are desired

in positive or negative form.

There are two processes resembling the photolithographic and photogelatin processes, but adapted to the reproduction of large black-on-white drawings or maps. The first is the reversing positive or Van Dyke process. It sometimes happens that there will be some advantage in making a photo-offset metal sheet directly from a black-on-white original. This is especially likely to be useful in the reproduction of maps. A British army engineer by the name of Van Dyke devised a method for preparing a metal sheet without a photographic negative of the master copy.

The process is first to coat the metal sheet with bichromated fish glue and then to make a photographic print on it from an original tracing or photopositive instead of a negative. The glue is hardened, not on the lines and letters, but around them. On the lines and letters the metal is cleaned bare. If such a sheet were put directly on the press it would print a black background, leaving the letters white, for the bare metal would accept water and the glue would accept ink.

But the printing quality of the

surface can be reversed by an ingenious de-

vice. First, the whole surface is covered

with ink, no part of it being moistened

with water. The bare metal, unprotected by

moisture, takes as much ink as the hardened

glue. If the sheet were used in that state,

it would cover the whole paper solid black. ∥

Then comes the reversing step. Some of the ink is sticking directly to the metal; the rest is held to the metal only by the film of glue. If the glue is eaten away, the ink will fall off. An acid bath will attack the glue without touching the ink that has adhered directly to the metal. The metal sheet is immersed in acid, and when the acid has done its work the hardened glue falls off, bearing the ink with it. The metal then shows a surface of lines or letters formed in ink with bare metal between them. If this sheet is put on the offset press and the bare metal moistened with water, it will print like any other photolithographic sheet. The inked parts of the metal continue taking ink, the moistened parts continue taking water and rejecting ink.

A process which has been called

Ordoverax and is given the name Lithoprint

by the Lithoprint Company of New York, Inc.,

4] Warren Street, New York City, is the

second of these methods. As dermaprint arrives as a gelatin adaptation of the mimeograph, so the Ordoverax process appears as

a gelatin adaptation of blueprinting techniques. The process does not seem to have

much currency in America except in the books

about techniques, but its possibilities are

interesting. A gelatin-covered plate is

reduced to a gummy condition at a low temperature. An exposed but undeveloped blueprint will transfer its lines to a gelatin

surface so that the gelatin surface will

become differentially receptive to ink,

like a developed photolithographic metal

sheet. The same result can be obtained by

bringing a gelatin surface into contact

with a certain chemical ink. Typewriter

ribbons can be impregnated with the active

chemical. The process ought to fit very

well in the no-man’s land of reprinting

techniques between five and twenty-five

copies. It is curious that the principle

has not been developed as an improvement ∣

p.66

of the hectograph, for the hectograph already uses a gelatin surface. Price data

on the process are not easily obtainable,

nor are the writers certain of any firm

that uses it, although certain blueprint

firms claiming to do work by “secret” processes may be using this one.

p.66

of the hectograph, for the hectograph already uses a gelatin surface. Price data

on the process are not easily obtainable,

nor are the writers certain of any firm

that uses it, although certain blueprint

firms claiming to do work by “secret” processes may be using this one.

The Van Dyke process is used principally for map work, the lithoprint method for multiplying drawings upon linen. The costs of both processes act like normal book production costs: there is a large initial cost in preparing the copy and a smaller running cost for the production of additional copies. The Lithoprint Company charges $.06 per square foot in quantities of six copies or over, with a minimum charge of one square foot for each drawing. The purchaser does not get the advantage of declining costs with the increase of edition size beyond six.

A third process, which is known by several trade names, uses a direct-on-tracing-cloth method. It is a process whereby a Van Dyke negative is employed. The Van Dyke negative is placed upon a sensitized tracing cloth, which is exposed to light in a vacuum frame, developed, and washed. From this waterproof tracing cloth, a number of blueprints can be made, and the need for hand tracing is entirely eliminated. Prices for tracing-cloth reproductions start at $.65 per square foot, with reductions in price starting at fifty square feet.

Blueprinting and Photostating (First Costs Low, Running Costs High)

Most of the processes of the blueprint type exhibit a different kind of cost

behavior, resembling manuscript costs of

the period prior to the invention of printing. The second copy costs almost as much

as the first copy; there are very small

savings to be obtained by increasing the

size of the edition. This situation is

normal in all those photographic processes

which count upon sensitizing the surface

of the paper that is to be used rather than

sensitizing the printing surface and then

printing with ink on ordinary paper. The

machinery for making copies by these processes is always some kind of frame in which

the original and the sensitive paper are

held in contact and exposed to light. The

costs are usually quoted in square feet. ∥

The differences are principally differences in the character of the sensitized surface spread on the paper.

The differences are principally differences in the character of the sensitized surface spread on the paper.

There are two ways of transferring an image to sensitized paper: directly, by holding the sensitive surface in contact with the text that is to be copied and forcing the light through it; indirectly, by using a lens, and reflecting light from the text to the sensitized surface. The most common of the direct methods is the blueprint technique, the most common of the indirect methods the photostat. The direct methods always reproduce the original without altering its size; the indirect methods permit enlargement or reduction.

There are four kinds of sensitive surface that are used commonly for making copies “directly” by light transmitted through the master copy (i.e., blueprinting). These are:

- Ferroprussiate (blueprint)

- Ferrogallic (indigo black print or gallic print)

- Sepia, sometimes called Van Dyke

- Ozalid and BW paper

The ferroprussiate sensitive paper

for blueprinting is often manufactured by

the blueprinting companies themselves, according to various formulae which yield

surfaces of different degrees of sensitivity. It is darkened by exposure to the

light and fixed by washing in water. The

ferrogallic print is made in the same way,

but it is more costly and is not used much

in this country. It also has the disadvantage that it is not permanent and that it

requires very careful timing of exposure

to prevent spoilage. The sepia print surface is sensitized with silver salts and

therefore bears a certain chemical resemblance to photostat paper. All these sensitized surfaces are alike in that they

will make a white-on-dark copy of a black-on-white object. Ozalid paper is exposed

exactly as if it were a blueprint paper;

then it is placed in an airtight box in

which ammonia fumes are released. The ammonia fumes darken to a dark red the lines

on the paper that have not been exposed to

light. Therefore a dark-on-white copy can

be made at one step from a black-on-white

original. ∣

p.[66a]

p.[66a]

∣p.[66b]

(blank)

∣p.[66c]

(blank)

∣

p.[66d]

p.[66d]

A number of possible manipulations ∣

p.67

permit a variety of results in copying by one or another of the blueprint

techniques. The original copy must

always be a strong black-on-white, and

the paper or cloth must be reasonably

translucent. By making from this original black-on-white a white-on-brown

sepia (Van Dyke) copy, and then using

the white-on-brown “negative” sepia

copy for producing additional blue or

sepia (Van Dyke) “positive” prints,

the blueprint technician can produce

copies that resemble the original in

being dark on a white ground. The B-W

process is simply a short-cut to this

result.

p.67

permit a variety of results in copying by one or another of the blueprint

techniques. The original copy must

always be a strong black-on-white, and

the paper or cloth must be reasonably

translucent. By making from this original black-on-white a white-on-brown

sepia (Van Dyke) copy, and then using

the white-on-brown “negative” sepia

copy for producing additional blue or

sepia (Van Dyke) “positive” prints,

the blueprint technician can produce

copies that resemble the original in

being dark on a white ground. The B-W

process is simply a short-cut to this

result.

In the terminology of the trade, a “blueprint” is always a print in which white lines appear on a blue ground. reverse of a blueprint is a “blue line print,” in which blue lines appear on a white ground. The B-W process yields a black line on white, and Ozalid gives a deep red line on white. In making a blue line print, it is customary to make first a Van Dyke negative (white lines on dark ground), and then, in a second exposure, make a blue line print from the Van Dyke negative. If a dark brown line is desired instead of a blue line, the paper used in the second exposure is the more expensive Van Dyke or sepia. The blue line and the brown line prints cost more than ordinary blueprints because they must be run more slowly through the machine. A photostat negative can be used in making a blue line or Van Dyke print, but the results are inferior. If, however, the photostat negative is made with a “paper negative” paper, such as the Kodalith or Photostat N paper, the results are equal to those obtained with a Van Dyke negative.

The production of blue line or Van

Dyke prints from paper negatives offers

very interesting possibilities in the reprinting of books in very small editions.

Unfortunately, it is impossible to get accurate price data, for the cost of production of paper negatives of this type is always included in the price of photo-offset

work. The paper negative that can be used

in the blueprint technique is exactly the

same as the paper negative used in photo-offset work. Since prices are not quoted

in the trade, it is necessary to make estimates of cost. ∥

The cost per square foot of paper negative is about three times the cost of photostat paper. The paper negative can be purchased in long rolls and used in the photostat. The cost of changing from one paper to the other in a photostat would be substantial, but it would be absorbed if the total amount of work to be done would be enough to use up a whole roll of paper negative—300 to 500 square feet. Apart from the loading of the roll of paper, there should be no labor costs to render the paper negatives more expensive than photostat negatives. The formula for the lowest reasonable price for paper negatives should therefore stand about as follows: multiply the cost of the paper by three and add the same non-paper cost (labor, chemicals, overhead, profit) that is shown on a photostat price list. An ordinary photostat 8½”) x 11” costs $.25 a page if one to five pages are ordered, and $.15 a page if 100 or more are ordered. There is no point in considering the production of a few pages, because of the labor cost of changing the paper in the machine. In the 100-page unit, the cost of photostat paper is $3.34, while the price of the finished photostat copies is $15.00. If the higher-priced paper negatives were used instead of photostat paper, the paper cost would be about $10.00, or $6.66 more than the ordinary paper; then the price of the finished copies could not be less than $21.66, and would probably be more.

Another way of figuring the differences is to consider the quoted price of

photostats utilizing a roll of paper 350′

x 18”. The ordinary paper costs $18.70 in

this amount, and the paper negative $50.50.

This amount of paper is used in photostat

work that, at ordinary prices, costs $119.00.

The substitution of paper negative for ordinary photostat paper should increase this

price by $31.80, bringing the total to

$150.80 instead of $119.00. It is evident

that the paper negative must cost about 50%

more than the ordinary photostat paper. If

the trade should develop business in this

line, the differential would probably be

greater, but for purposes of estimating in

this chapter, the 50% differential will be

used. It will be assumed that if photostats could be made for $100.00, the same

material could be put on paper negatives

for $150.00. ∣

p.67

p.67

Maximum Use of Area

The standard dimensions in which square footage measurements and prices are calculated in the blueprint industry are shown on the chart. Any area over 42” in width gives rise to a surcharge. The ordinary book or typescript page is too small a unit area to utilize the blueprint economically, but pages can be pasted together in large sheets to fit one or another of the fixed dimensions that are the basis of the price structure. Thus it would cost $.03 to blueprint a page 6” x 9”; but if four such pages were pasted together, the area of 18” x 12” would be blueprinted for $.045, a price per page of $.0125 instead of $.03.

The master copy for a book to be reproduced by the blueprint technique should always be envisaged as a large sheet consisting of pages pasted together. The large sheet can then be folded and cut and bound with the fold at the outside edge—a style of binding used in Chinese book publishing. This makes a book with each page doubled, so that the blank surface is folded in. The blueprint book will then offer the reader the convenience of a book with printing on both sides of the page. Another method is simply to cut up the large blueprint sheets into separate pages.

In blueprinting, as in photo-offset, the master copy can be a photostat negative. It may be an enlargement or a reduction from the size of the original text. The principle of maximum utilization of area requires that the pages be of such size that they will fit without wastage on one of the blueprint areas. Blueprint reproduction is well adapted to the production of editions of less than fifty copies.

Prices per Square Foot

Without losing sight of the fact that the copy must be made to fit the standard dimensions of the industry in order to obtain effective square footage prices, the calculation of the cost of multiplying texts by the different blueprint techniques can be made from the following price list.

Though the blueprint processes have

not been used in book production, they have

been used in a number of cases to duplicate

records. They have been called into service by college registrars to make transcripts of academic records. Mr. Daniel ∥

Rich of the University of Michigan has compiled a statement of the relative merits

of the B-W process and the photostat for

making these copies. Registrar E. B.

Stevens of the University of Washington

found that he could make copies of transcripts at $.075 each by the B-W process,

counting cost of labor and material. There

is a society which collects biographical

material by interviews with prospects who

are flattered by being told that they are

distinguished people. The society then deposits the biographical notes in a central

office, from which it offers to distribute

B-W copies. These uses of the B-W process

indicate a most interesting quality. When

material is deposited in the form of loose

sheets written in strong black on the right

kind of white paper, the B-W process will

permit the making of inexpensive copies of

the original upon demand.

Rich of the University of Michigan has compiled a statement of the relative merits

of the B-W process and the photostat for

making these copies. Registrar E. B.

Stevens of the University of Washington

found that he could make copies of transcripts at $.075 each by the B-W process,

counting cost of labor and material. There

is a society which collects biographical

material by interviews with prospects who

are flattered by being told that they are

distinguished people. The society then deposits the biographical notes in a central

office, from which it offers to distribute

B-W copies. These uses of the B-W process

indicate a most interesting quality. When

material is deposited in the form of loose

sheets written in strong black on the right

kind of white paper, the B-W process will

permit the making of inexpensive copies of

the original upon demand.

Copying of Documents without a Camera

a) Direct Contact Copying

There are two ways of directly copying documents without the use of a camera and, hence, without reduction or enlargement. If the original document is printed on one side of the page and the page has a fair degree of uniformity and transparency, a contact print can be made from it directly and using a minimum of equipment if a paper such as Insurance Bromide (sold by Eastman), Ad Type paper (Eastman), or Kodalith paper (Eastman) is used. This is a valuable process for the individual scholar who may wish to make copies with a minimum of equipment, whether in his own home or study or where photostat service is not available. It is a process well-suited to the copying of music written on one side of the sheet, for the musician may wish to make a photographic copy of borrowed sheet music.

The cost of materials is simply the

cost of the photographic paper plus the

chemicals. The equipment is cheap and consists of a safelight, printing frame, or

sheet of thick plate glass, and convenient

dishes for developing, washing, and fixing.

Any darkened room will serve for the work.

It should preferably be equipped with electric lighting so that two points or a double plug are available, one for any ordinary electric light bulb and the other for

the safelight or red bulb lamp. ∣

p.69

p.69

TABLE XXV

TABLE XXVI

PRICES PER SQUARE FOOT OF BLUEPRINT AND ALLIED PROCESSES*

| Process | Form of Original | Form of Copy | Running Cost of Prints |

|---|---|---|---|

| Blueprint on Paper | Black on translucent white, text on one side of page only (as typescript or drawing on linen) | White on blue | $.03 square foot; $.04 sq. ft. in widths over 42” |

| Van Dyke Negative | ” | White on brown | $.08 square foot; $.10 sq. ft. in widths over 42” |

| Ferro-gallic | ” | Black on white | Perishable; not recommended |

| Lithoprint | ” | Black on white | $.06 square foot in quantities of six or more |

| B-W and Ozalid** | ” | Black on white | $.05 square foot; $.06 sq. ft. in widths over 42” |

| Van Dyke Positive | Paper negative (as for photo-offset) at $.30 - $.37 per sq. ft.; Van Dyke negative at $.08 sq. ft. | Brown on white | $.10 square foot; $.12 sq. ft. in widths over 42”. First copy with paper negative will cost $.40-$.47 per sq. ft., and $.10 each additional ft.; first copy with Van Dykes will cost $.18 per sq. ft., and $.10 for each additional |

| Blue Line Print (positive) | Same as for Van Dyke positive | Blue on white | $.05 square foot; $.06 sq. ft. in widths over 42”. First copy with paper negative will cost $.35-$.42 per sq. ft.; and $.05 each additional; first copy with Van Dyke negative will cost $.13 sq. ft., and $.05 each additional |

| Photostat Negative (8½ x 11”) | (Method of calculating prices is not strictly comparable, but for approximate comparisons, price of one copy is given) | $.20 - $.25. Note that this will vary with successive full use of area and with size of job | |

| Photostat Positive (8½ x 11”) from same negative | $.20 - $.25. Full use of area easily achieved; variation principally with size of job. First positive will cost $.40 - $.50, and each additional will cost $.20 - $.25 |

* Usually there is a minimum order per print of one square foot, and a service and handling charge on orders of less than 100 square feet.

** Prints curl.

In the case of documents which have become yellow with age, improved results can often be obtained by printing through a yellow glass such as the Wratten No. 12 filter or the Wratten Series 00 safelight. In such a case the prints are best made on a paper sensitive to green light such as Kodalith Ortho or Insurance Bromide. Even a lighted match can serve as a source of light in this direct method.

In copying an ordinary page, say of typescript, a piece of photographic printing paper is laid face up and the typescript paper face up on top of it. The two are held together with a piece of glass or in a printing frame, and the light is turned on over them for the appropriate time. The paper is then developed and fixed and comes out as a negative copy not unlike a photostat copy, though with less definition and contrast. The definition is not so good because the thickness of the photographic paper comes in between the surface it is desired to copy and the sensitive surface. If the paper is very thick, or of very close texture, or very dense, then it will be practically impossible to obtain good sharp negatives in this way. In these circumstances it will be necessary to place the printed side of the page in contact with the sensitive paper, print for the required time, and develop to a negative which will be laterally reversed. In order to secure a final positive, a contact print will have to be made from this on another sheet of paper.

b) Reflection Copying

If the page from which the copy is to be made is printed on both sides, then a different process is necessary. Clearly it would not be possible to print through the page. The process to be employed in this case is known as the “reflection copying” or “reflex” process and was originally known as the “Playertype” since it was first put to practical use by an Englishman named Player towards the end of the last century.

In this process a piece of black

paper is placed under the page to be copied

and a piece of photographic paper of high

contrast and orthochromatic, such as

Kodalith Ortho (Eastman) or Insurance Bromide, on single weight support is placed

face down on top of it with the emulsion ∥

side of the photographic paper in contact

with the printed surface it is desired to

reproduce. The two must then be pressed

into very close contact with a heavy piece

of plate glass or in a pressure printing

frame. This can be helped by using a thin

sheet of felt behind the black paper under

the page to be copied. The exposure to

light is made through the back side of the

photographic paper, the exposure depending,

of course, on the light source and the distance from it and the speed of the paper

used. If the copy obtained in this way is

developed, fixed, washed, and dried, it will

be a laterally reversed image of the page,

and it can be used to make an unreversed

positive copy of the page by making a contact print from it on another piece of paper. It is not absolutely necessary to

make a positive, although it is usually

more convenient to do so. The negatives

may be read by a transmitted light, especially if the paper is on a fairly translucent single-weight support. The contact

print from the original negative can be

made while the negative is still wet after

washing, and in this way time can be saved.

side of the photographic paper in contact

with the printed surface it is desired to

reproduce. The two must then be pressed

into very close contact with a heavy piece

of plate glass or in a pressure printing

frame. This can be helped by using a thin

sheet of felt behind the black paper under

the page to be copied. The exposure to

light is made through the back side of the

photographic paper, the exposure depending,

of course, on the light source and the distance from it and the speed of the paper

used. If the copy obtained in this way is

developed, fixed, washed, and dried, it will

be a laterally reversed image of the page,

and it can be used to make an unreversed

positive copy of the page by making a contact print from it on another piece of paper. It is not absolutely necessary to

make a positive, although it is usually

more convenient to do so. The negatives

may be read by a transmitted light, especially if the paper is on a fairly translucent single-weight support. The contact

print from the original negative can be

made while the negative is still wet after

washing, and in this way time can be saved.

The contrast in this process can be improved considerably if the original negative is made by printing in yellow light rather than white light. For this purpose the Wratten Series 00 safelight or the Wratten No. 12 filter is quite satisfactory, and the printing paper must be orthochromatic such as Kodalith Ortho or Insurance Bromide. A suitable printing lamp can be made by using a regular pyramid safelight containing the Series 00 glass, and costing $3.00.

The cost of copying pages) by this method as compared with copying pages printed on one side only of a thin sheet of paper is in the extra sheet of bromide paper required.

The Photostat

The best established of the copying

methods on photosensitive paper is the

photostat method. In the photostat as in

the blueprint processes, the unit cost does

not diminish as the size of the edition increases. But it can be made to diminish by

reducing the dimensions of the pages copied,

and hence cutting down at once on the legibility of the finished product and the area

of the photographic paper used. This ∣

p.72

possibility raises in connection with the

photostat the same problem of reduction of

type size that appeared in connection with

photolithography.

p.72

possibility raises in connection with the

photostat the same problem of reduction of

type size that appeared in connection with

photolithography.

In photostating, operating and equipment costs both enter into consideration, for the photostat apparatus is often owned and operated by research institutions themselves.

The costs of photostatic copies are governed principally by the cost of the photostat paper. The price per square foot of a light-weight stock is about $.04, But in the preservation of research materials use may be made of the special “H” or “HH” grade of permanent paper stock, manufactured by the Byron Weston Company. The “H” grade, which is coated on one side, sells for $.052 per square foot; the “HH” grade, which is coated on both sides and hence will bring a saving of half the cost of binding the volumes, sells for $.092 per square foot of paper or #.04 ¾ per square foot of sensitive surface.

When wastage has been taken into account and the variations due to the different ways of imposing the negative and cutting the paper from rolls of different widths has been reckoned with, the cost of paper for photostating a 100—page book in different page sizes and with different grades of paper is as follows below.

To these costs of paper there must

added the costs of labor and chemicals.

The New York Public Library and the printing department of the Cleveland Bell Telephone Company very kindly contributed ∥

statements of their operating costs. In

the New York Public Library the great majority of the prints were 11½” by 14”,

usually one copy only, and the average cost

of the paper was $.055. In the Telephone

Company the average size of paper was

8½” x 11”, and in many cases several

copies of the same object were required.

The cost of the paper averaged $.03 per

page. In the Public Library the $.055

worth of paper requires so much reference

and clerical work that the cost of the finished print rises to $.193 each. In the

Telephone Company, where only operating

room charges need be considered, the $.03

worth of paper is worked up into a print

which costs $.063. This means that labor,

depreciation, and chemical supplies cost

$.033. These operating room costs in the

Public Library amount to $.06. The figures

in total operating room cost are as follows:

statements of their operating costs. In

the New York Public Library the great majority of the prints were 11½” by 14”,

usually one copy only, and the average cost

of the paper was $.055. In the Telephone

Company the average size of paper was

8½” x 11”, and in many cases several

copies of the same object were required.

The cost of the paper averaged $.03 per

page. In the Public Library the $.055

worth of paper requires so much reference

and clerical work that the cost of the finished print rises to $.193 each. In the

Telephone Company, where only operating

room charges need be considered, the $.03

worth of paper is worked up into a print

which costs $.063. This means that labor,

depreciation, and chemical supplies cost

$.033. These operating room costs in the

Public Library amount to $.06. The figures

in total operating room cost are as follows:

| Library | Telephone Co. | |

|---|---|---|

| Paper (per 100 pages) | $5.50 | $3.00 |

| Operating costs (“) | 6.00 | 3.30 |

| $11.50 | $6.30 | |

| Cost per square foot for paper, labor, and chemicals | $0.10 | $0.084 |

The Public Library spends an additional $.082 on every page to cover clerical help, postage, and desk supplies–charges which are due to the special character of the

TABLE XXVII

COSTS OF PHOTOSTAT PAPER TO PRODUCE A BOOK OF 100 PAGES, IN DIFFERENT PAGE SIZES AND WITH DIFFERENT GRADES OF PAPER USED

| Dimensions of Book Page in Inches | Ordinary Stock | “H” Stock | “HH” Stock (Used on Both Sides) |

| 4½” x 8” | $ .62 to $ .82 | $ .99 to $1.04 | $ .91 |

| 5½” x 8” | 1.22 to 1.51 | 1.72 to 1.95 | 1.57 to 1.91 |

| 6” x 9” | 1.40 to 1.83 | 1.97 to 2.06 | 1.81 to 2.35 |

| 8½” x 11” | 2.41 to 3.00 | 3.38 to 3.73 | 3.09 to 3.81 |

| 11” x 14” | 3.95 to 5.01 | 5.57 to 6.22 | 5.09 to 6.08 |

| 11” x 17” | 4.81 to 7.68 | 6.76 to 9.55 | 6.18 |

| 18” x 22” (page of New York Times) | 10.18 | 14.30 |

∣p.[72a]

(blank)

∣

p.[72b]

p.[72b]

FIGURE XXXVIII

The Photostat

∣p.[72c]

(blank)

∣

p.[72d]

p.[72d]

FIGURE XXXIX

∣

p.73

library work. The inescapable operating

costs are 10% more than the cost of the paper and may be more than twice the cost of

the paper. This percentage is reduced as

the work becomes more continuous. The life

insurance companies operate with highly

standardized copy; their labor costs should

be very low, but the writer has not been

able to secure statements from them. The

work of the Massachusetts Historical Society in copying colonial newspapers made

use of the photostat at its highest efficiency for the reproduction of research

materials. A letter from the director, Mr.

Worthington C. Ford, explains the financing

of this enterprise:

p.73

library work. The inescapable operating

costs are 10% more than the cost of the paper and may be more than twice the cost of

the paper. This percentage is reduced as

the work becomes more continuous. The life

insurance companies operate with highly

standardized copy; their labor costs should

be very low, but the writer has not been

able to secure statements from them. The

work of the Massachusetts Historical Society in copying colonial newspapers made

use of the photostat at its highest efficiency for the reproduction of research

materials. A letter from the director, Mr.

Worthington C. Ford, explains the financing

of this enterprise:

…we gave our operator the highest photostat salary paid within my knowledge and with that the cost of material represented twice the cost of labor. I roughly estimated that it cost us about $.13½ to make a page of a newspaper of the large size…but we printed some which required the largest size of sheet adaptable to the photostat machine, and the average cost was not increased. We sold the newspapers at a fixed price of $.15 per page. Some years there was a profit of $300–$400 and some years we came out even.

Similar newspaper photostating by the University of Michigan Library and John Carter Brown Library are being carried on at a rate higher than that charged by the Massachusetts Historical Society. The Library of Congress estimates that its photostat copies of foreign archive material cost it $.15 each, and the British Museum and Bodleian Libraries show a cost of $.06 a page quarto size. It can be concluded that every dollar’s worth of photostat paper requires from $.50 to $1.10 in operating expenses.

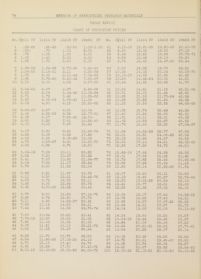

Commercial prices for photostating

service are standardized on the basis of

four sizes: 8½” x 11”; 11” x 14; 14”

x 18”; and 16” x 24”. The price falls

with the number of pages copied, from the

high of $.25 a page (8½” x 11”) when

one page only is copied, to the low of

$.15 when 100 pages are copied. The following table charts the prices of any number of pages from one to 100, in any of ∥

the four sizes. The price falls by $.01 a

page with every increment of five pages.

This table will be used in making estimates

of cost of photostat work, although actual

photostat service may be available at lower prices in some places, or may cost more

elsewhere. A spread of two book pages, 6”

x 9”, will go on a photostat page 14” x 18”.

If slightly reduced in size, two pages

would go on one photostat page 11” x 14”.

the four sizes. The price falls by $.01 a

page with every increment of five pages.

This table will be used in making estimates

of cost of photostat work, although actual

photostat service may be available at lower prices in some places, or may cost more

elsewhere. A spread of two book pages, 6”

x 9”, will go on a photostat page 14” x 18”.

If slightly reduced in size, two pages

would go on one photostat page 11” x 14”.

The “number” is the number of photostat sheets, and may be either duplications of the same pages or reproductions of successive pages of a book. The price is the total price of the number of sheets, but opposite each price group is a unit cost figure indicating price-per-page.

Photocopying Equipment

The two appliances which compete in the field of photographic copying are the photostat (Figure XXXVIII) and the Rectigraph (Figure XXXIX). The photostat is the better known and has succeeded in making a common noun of its trade name. The differences between the two kinds of apparatus do not seem to be sufficiently important to have a decisive effect upon costs but are worth noting because they illustrate certain of the practical aspects of photostat work.

Both firms have two kinds of apparatus: a standard equipment, which leaves it to the operator to shift the prints to a rinsing tank and to dry them; and a “continuous photostat” or “super Rectigraph,” which carries the prints automatically through the whole process from exposure to drying. The highest-priced continuous photostat costs $4000.00. The claim is made that it will turn out three prints a minute. The “super Rectigraph” costing $2600.00, is said to deliver prints completely fixed, washed, and dried at the rate of one a minute.

The following are the principal

differences between the two machines. The

photostat carries the print on an endless

chain through a developed bath, then

through a chromium roller which squeezes

out the surplus developer, into a rinsing

tank of running water, and then face down

into a shallow fixing tank which is continuously agitated by a motor. The Rectigraph apparatus grasps the end of the paper and pushes it down into the developer, ∣

p.74

p.74

TABLE XXVIII

CHART OF PHOTOSTAT PRICES

| No. | 8½x11 PP | 11x14 PP | 14x18 PP | 18x24 PP | No. | 8½x11 PP | 11x14 PP | 14x18 PP | 18x24 PP |

|---|---|---|---|---|---|---|---|---|---|

| 1 | .25-25 | .35-35 | .50-50 | 1.00-1.00 | 51 | 9.15-18 | 12.81-25 | 18.30-36 | 36.60-72 |

| 2 | .50- | .70 | 1.00 | 2.00 | 52 | 9.30 | 13.02 | 18.60 | 37.19 |

| 3 | .75 | 1.05 | 1.50 | 3.00 | 53 | 9.44 | 13.22 | 18.89 | 37.78-71 |

| 4 | 1.00 | 1.40 | 2.00 | 4.00 | 54 | 9.59 | 13.43 | 19.18 | 38.36 |

| 5 | 1.25 | 1.75 | 2.50 | 5.00 | 55 | 9.74 | 13.63 | 19.47-35 | 38.94 |

| 6 | 1.35-23 | 1.89-32 | 2.70-45 | 5.40-90 | 56 | 9.88 | 13.83 | 19.76 | 39.51 |

| 7 | 1.56-22 | 2.18-31 | 3.11 | 6.22-89 | 57 | 10.02 | 14.03 | 20.04 | 40.08-70 |

| 8 | 1.76 | 2.45 | 3.51-44 | 7.02-88 | 58 | 10.16-17 | 14.23 | 20.32 | 40.65 |

| 9 | 1.95 | 2.73-30 | 3.90-43 | 7.80-87 | 59 | 10.30 | 14.42-24 | 20.60 | 41.21 |

| 10 | 2.15 | 3.00 | 4.29 | 8.57-86 | 60 | 10.44 | 14.62 | 20.88 | 41.76 |

| 11 | 2.34-21 | 3.27 | 4.67 | 9.33-85 | 61 | 10.58 | 14.81 | 21.15 | 42.31-69 |

| 12 | 2.52 | 3.53 | 5.04-42 | 10.08-84 | 62 | 10.71 | 15.00 | 21.43 | 42.85 |

| 13 | 2.71 | 3.79 | 5.42 | 10.83-83 | 63 | 10.85 | 15.19 | 21.70-34 | 43.39 |

| 14 | 2.90 | 4.05-29 | 5.79-41 | 11.58 | 64 | 10.98 | 15.38 | 21.96 | 43.93 |

| 15 | 3.08 | 4.30 | 6.15 | 12.30-82 | 65 | 11.12 | 15.56 | 22.23 | 44.46-68 |

| 16 | 3.26-20 | 4.57 | 6.52 | 13.04 | 66 | 11.25 | 15.74 | 22.49 | 44.99 |

| 17 | 3.45 | 4.82-28 | 6.89 | 13.77-81 | 67 | 11.40 | 15.96 | 22.80 | 45.61 |

| 18 | 3.63 | 5.07 | 7.25-40 | 14.50- | 68 | 11.51 | 16.11 | 23.01 | 46.02 |

| 19 | 3.81 | 5.32 | 7.61 | 15.22-80 | 69 | 11.63 | 16.29 | 23.27 | 46.53 |

| 20 | 4.00 | 5.58 | 7.97 | 15.94 | 70 | 11.76 | 16.46 | 23.52 | 47.04-67 |

| 21 | 4.17 | 5.80 | 8.33 | 16.66-79 | 71 | 11.89 | 16.64-23 | 23.77 | 47.54 |

| 22 | 4.35 | 6.08 | 8.69 | 17.38 | 72 | 12.01 | 16.81 | 24.02-33 | 48.04 |

| 23 | 4.53 | 6.32 | 9.05-69 | 18.09 | 73 | 12.13 | 16.99 | 24.27 | 48.53 |

| 24 | 4.70 | 6.58-27 | 9.40 | 18.80-78 | 74 | 12.25 | 17.16 | 24.51 | 49.02-66 |

| 25 | 4.88 | 6.82 | 9.75 | 19.50 | 75 | 12.38 | 17.33 | 24.75 | 49.50 |

| 26 | 5.04-19 | 7.08 | 10.11 | 20.22 | 76 | 12.49-16 | 17.49 | 24.99 | 49.98 |

| 27 | 5.23 | 7.33 | 10.47 | 20.93 | 77 | 12.61 | 17.66 | 25.23 | 50.45 |

| 28 | 5.41 | 7.57 | 10.82 | 21.64-77 | 78 | 12.73 | 17.82 | 25.46 | 50.92-65 |

| 29 | 5.59 | 7.82 | 11.17 | 22.34 | 79 | 12.85 | 17.98 | 25.69 | 51.38 |

| 30 | 5.76 | 8.06 | 11.52 | 23.04 | 80 | 12.96 | 18.14 | 25.92-32 | 51.84 |

| 31 | 5.93 | 8.31 | 11.87 | 23.73 | 81 | 13.07 | 18.30 | 26.15 | 52.29 |

| 32 | 6.11 | 8.55 | 12.21 | 24.42-76 | 82 | 13.19 | 18.46 | 26.37 | 52.74-64 |

| 33 | 6.28 | 8.79 | 12.55 | 25.11 | 83 | 13.30 | 18.62-22 | 26.59 | 53.19 |

| 34 | 6.45 | 9.02 | 12.89 | 25.79 | 84 | 13.41 | 18.77 | 26.81 | 53.63 |

| 35 | 6.62 | 9.26-26 | 13.23 | 26.46 | 85 | 13.52 | 18.92 | 27.03 | 54.06 |

| 36 | 6.78 | 9.50 | 18.56 | 27.13-75 | 86 | 13.62 | 19.07 | 27.24 | 54.49-63 |

| 37 | 6.95 | 9.73 | 13.90 | 27.79 | 87 | 13.73 | 19.22 | 27.46 | 54.91 |

| 38 | 7.11 | 9.96 | 14.23-37 | 28.45 | 88 | 13.83 | 19.37 | 27.67-31 | 55.33 |

| 39 | 7.28 | 10.19 | 14.55 | 29.11 | 89 | 13.94 | 19.51 | 27.87 | 55.75 |

| 40 | 7.44 | 10.42 | 14.88 | 29.76-74 | 90 | 14.04 | 19.66 | 28.08 | 56.16-62 |

| 41 | 7.60 | 10.64 | 15.20 | 30.41 | 91 | 14.14 | 19.80 | 28.28 | 56.57 |

| 42 | 7.76-18 | 10.87 | 15.52 | 31.05 | 92 | 14.24-15 | 19.94 | 28.48 | 56.97 |

| 43 | 7.92 | 11.09 | 15.84 | 31.68 | 93 | 14.34 | 20.08 | 28.68 | 57.36 |

| 44 | 8.08 | 11.31 | 16.16 | 32.31-73 | 94 | 14.44 | 20.21-21 | 28.88 | 57.75-61 |

| 45 | 8.24 | 11.53 | 16.47 | 32.94 | 95 | 14.54 | 20.35 | 29.07 | 58.14 |

| 46 | 8.39 | 11.75 | 16.78 | 33.56 | 96 | 14.63 | 20.48 | 29.26 | 58.52 |

| 47 | 8.54 | 11.96-25 | 17.09-36 | 34.18 | 97 | 14.72 | 20.61 | 29.45-30 | 58.90 |

| 48 | 8.70 | 12.18 | 17.40 | 34.79 | 98 | 14.82 | 20.74 | 29.64 | 59.27 |

| 49 | 8.85 | 12.39 | 17.70 | 35.40-72 | 99 | 14.91 | 20.87 | 29.82 | 59.64-60 |

| 50 | 9.00-18 | 12.60-25 | 18.00-36 | 36.00-72 | 100 | 15.00-15 | 21.00-21 | 30.00-30 | 60.00-60 |

∣

p.75

withdraws it up again by the same end,

passes it through a roller (but not a bath

of running water), covers its surface with

the fixing solution, and lets it emerge

face up in a deep fixing tank. All these

features are interrelated. An advantage

of the Rectigraph setup is that as each

print is made, it can be examined immediately to determine if it is satisfactory,

thus eliminating considerable wastage. The

Rectigraph uses a deeper tank because the

solution is allowed to lie still; the photostat agitates the tank, which must therefore be shallow. The Rectigraph claims

that it can dispense with the agitating of

the fixing bath because it covers the whole

surface of the paper evenly with the solution before it enters the bath. It is

this covering of the surface prior to immersion in the bath which permits the print

to appear face up in the tank. The photostat has a much heavier frame, which is

necessary to resist the vibration caused

by the agitating of the tank, but which has

The Rectigraph wastes more paper than the photostat

because it requires more of a margin at the

top of the sheet when dipping it into the

developer. Each company claims that it is

more saving of chemicals. In the judgment

of the writer, the photostat has the better claim because the developer is washed

off in running water before the print enters the fixing tank; although Rectigraph

points out that their chemicals last longer

because the tank does not expose as much

surface to the air for deterioration.

p.75

withdraws it up again by the same end,

passes it through a roller (but not a bath

of running water), covers its surface with

the fixing solution, and lets it emerge

face up in a deep fixing tank. All these

features are interrelated. An advantage

of the Rectigraph setup is that as each

print is made, it can be examined immediately to determine if it is satisfactory,

thus eliminating considerable wastage. The

Rectigraph uses a deeper tank because the

solution is allowed to lie still; the photostat agitates the tank, which must therefore be shallow. The Rectigraph claims

that it can dispense with the agitating of

the fixing bath because it covers the whole

surface of the paper evenly with the solution before it enters the bath. It is

this covering of the surface prior to immersion in the bath which permits the print

to appear face up in the tank. The photostat has a much heavier frame, which is

necessary to resist the vibration caused

by the agitating of the tank, but which has

The Rectigraph wastes more paper than the photostat

because it requires more of a margin at the

top of the sheet when dipping it into the

developer. Each company claims that it is

more saving of chemicals. In the judgment

of the writer, the photostat has the better claim because the developer is washed

off in running water before the print enters the fixing tank; although Rectigraph

points out that their chemicals last longer

because the tank does not expose as much

surface to the air for deterioration.

While it is true in general that the cost of photostat copies does not diminish as the edition increases in size, there is one significant exception. If the user demands a positive copy, the photostat process must provide first a negative and then make the positive from that. A positive copy therefore involves two steps and costs twice as much as a negative. If a number of positive copies are required, the cost of the negative can be distributed among them, thus reducing the cost of each.

On long jobs further economies in

the making of photostat positives can be

effected by reducing the original copy in

the negative and enlarging it back in the

positive. The reduction to one-half size

at the negative stage can result in two ∣

p.75

kinds of economy. Only one-fourth as much

paper is needed for the negative, and it is

often possible when copying back to positives to lay down four negatives at once,

copy them all at one exposure, and thus

save labor time. These possibilities do

not materially reduce the cost level of

photostat operations as compared with other processes.

p.75

kinds of economy. Only one-fourth as much

paper is needed for the negative, and it is

often possible when copying back to positives to lay down four negatives at once,

copy them all at one exposure, and thus

save labor time. These possibilities do

not materially reduce the cost level of

photostat operations as compared with other processes.

The most extreme use of the principle of making the negative small and enlarging it back in making the positive is the film-copying and enlarging process. If the negative copy is made with a very great reduction—say sixteen diameters—on film, it can be enlarged back on photostat paper with an ordinary film enlarger. This process will yield positive copies on photostat paper for very little more (in some cases for less) than the cost of the negative photostat. The combination of film copying with photostating is important because it redistributes the labor of making photographic copies. One man can go off into the wilds with a small camera to make film copies, while leaving the work of enlarging to be done at another time and place.

Although the apparatus has not yet been designed, it would be very easy to make a semi-automatic machine for enlarging from film to paper. The only equipment to be added to the standard enlarger would be an automatic stepping device to move the film, one frame at a time, before the lens. Large-scale copying work from film to paper has already demonstrated that one worker can do as many as 2000 sheets a day. With automatic apparatus this may be increased to 3000 pages. At such levels the costs of making positives on paper approach the materials costs, for ten dollars worth of labor will use up fifty dollars worth of materials. As will be pointed out in a later chapter, such cost situations introduce a temptation to reduce the size of the paper print to the lowest level of legibility.

Another automatic device is operated by the Recordak Corporation. This is a continuous process machine for transfering a roll of film to an enlarged roll of paper. This service brings the price of the photostat copy to a point very near the price of the photostat paper.

The whole field opened by film

copying in reduced sizes will be discussed

in a later chapter. For the present it is ∣

p.76

sufficient to note that film copying and

enlarging will yield positive copies on

photostat paper for approximately the price

of negative photostats.

p.76

sufficient to note that film copying and

enlarging will yield positive copies on

photostat paper for approximately the price

of negative photostats.

The Dexigraph

Another type of photocopying equipment is the Dexigraph, (Figure XL), manufactured by Remington Rand. It is a fixed focus camera, copying from a fixed size of object to a fixed size of copy. One of its principal uses in scholarship is for the reproduction of library catalogue cards, although as with the other photostatic apparatus, it is also used for registrars’ records, transcripts, etc.

Miss Anna M. Monrad, Head Cataloger of the Yale University Library, has written an article on the experience of Yale Library in using the Dexigraph to make an official catalogue.1 Miss Monrad’s article tells of experience with the automatic Dexigraph; Dr. Frederick Hicks, Law Librarian of Yale Law Library, in the article, “Reproduction of Catalogue Cards by Photographic Methods,”2 gives an account of experimentation with the Junior Dexigraph, using the machine as a substitute for the typewriter. Computations made for a six weeks! period indicated that dexigraphing 5,417 cards, including material, labor, chemicals, machine rental, and wastage, cost $.03507 per card (5,211 usable cards resulting); typing 5,211 cards cost $.033 per card. Dr. Hicks stated that even if the typing method were cheaper, the use of the Dexigraph would still be justified because of the factors of speed and accuracy. Other users include the Universities of California, Illinois, Missouri, and Notre Dame.

Dexigraph units are leased, not

sold. The Junior Dexigraph, handling copy

up to letter and legal size, is leased for

from $10.00 to $25.00 per month. With

this model an operator can Dexigraph from

200 x 400 prints an hour. The junior

Dexigraph is portable and occupies only a

few feet of space. The automatic Dexigraph

handles all copy from 7½cm. x 12½cm.

up to and including 8½” x 14”, and is

recommended for mass reproduction. The

rate of 3,000 cards an hour is claimed for ∥

it. It can be leased for a one-year period for $50.00 a month, but Remington Rand

ordinarily uses it on a contract basis

when a specific assignment for a job of

some magnitude is required.

it. It can be leased for a one-year period for $50.00 a month, but Remington Rand

ordinarily uses it on a contract basis

when a specific assignment for a job of

some magnitude is required.

Dexigraph copies, like photostat copies, are produced as negatives. Sensitized paper is used, and it comes in pre-cut or roll form. The price varies according to weight, size, and type of paper. Standard Record paper ranges in price from $6.80 per 1,000 sheets 5” x 3”, up to $32.00 for 1,000 sheets 8” x 8”; Permanent Record paper begins at $8.80 per 1,000 cards 5” x 3” and goes up to $39.75 for the 8” x 8” size; Duplex Permanent Record paper is more expensive. The roll paper is priced from $8.60 to $19.00, according to weight and size. Permanent Record paper is heavier than Standard Record paper and is sensitized on a paper stock resembling an all-rag stock. Dexigraph claims that the cost of labor, chemicals, material, etc., for centimeter cards should not exceed $.02 each where a quantity is involved; the legal size documents run about $.07 each. Both these figures include machine rental.

Through the use of a color filter, colored paper can be copied. The turn of a dial varies the amount of light entering and consequently determines the amount of contrast desired.

Ira W. Smith, in a report of April; 1934, on methods of duplicating records, says that the University of California at Berkeley used the Dexigraph and made prints at a cost of approximately $#.03 each, including cost of paper, developing materials, and labor, when the volume of work was fairly large. The cost when only a few prints were made at a time was about $.07 each.

The Technological Frontier

It is to be hoped that a means may

be found to combine the economies due to

saving of material in film copying with

those due to labor saving in the Dexigraph.

It should be possible to develop an automatic machine for enlarging film copies to

a fixed size. Such a device would bring

photostat costs down very close to mere

photostat paper costs. If such a device

should then be developed to take full

∣

p.[76a]

∣p.[76b]

(blank)

∣

p.[76a]

∣p.[76b]

(blank)

∣

p.77

advantage of the possibility of saving

photographic surface by reducing the size

of the reading matter, photostatic copies

might enter a new cost level and hence acquire a new importance in the strategy of

scholarship. The Joint Committee has

heard that there is some prospect of development along this line.

p.77

advantage of the possibility of saving

photographic surface by reducing the size

of the reading matter, photostatic copies

might enter a new cost level and hence acquire a new importance in the strategy of

scholarship. The Joint Committee has

heard that there is some prospect of development along this line.

FIGURE XL

The Dexigraph

Typescript can serve as the master copy from which B-W and blueprints are made, provided it is written with a very black ribbon. It can serve as master copy for the photostat process without special preparation. To bring together all the processes for multiplying a typescript book, it is only necessary to imagine that a typescript of 100,000 words as submitted for multiplication in the form of a fair copy, 334 pages, 8½” x 11”.

How shall this be multiplied? It can be retyped for the format copy and reproduced by hectograph, mimeograph, or photo-offset. It can be photostated full size, half size, or in some intermediate size. If it happens to be typed in sufficiently dark print on the right kind of paper, it can be reproduced directly by any of the blueprint processes. If it is not sufficiently contrasted for the direct use of a blueprint process, it can be photostated and blueprints made from the photostat negatives. Each of these processes will result in a legible product; the exact differential in legibility is difficult to estimate. Each of them will exhibit its principal cost advantages at a particular part of the rising curve of edition size.

Comparative Costs in Book Production

It is now possible to compare costs of blueprint, photostat, and photo-offset in book production.

The original to be reproduced may be either a printed book or a.pile of typescript. An octavo book of 100,000 words, 6” x 9” page, with 400 words to the page would cover ninety-four square feet. A typescript of normal format, 300 words to the page, would require 334 pages, 8½” x 11”, or 217 square feet.

The alternatives that present themselves in the reproduction of these texts are (a) typescript copying, (b) photostat, (c) blueprinting, and (d) photo-offset.

Six of these processes (blueprint,

blue line print, Van Dyke negative, Van ∥

Dyke positive, B-W, and Ozalid) are incapable of enlarging copy or reducing it, and

equally incapable of dealing with such a

thing as a book with pages printed on both

sides. Those that involve the use of the

photostat are adapted not only to the reproduction of book pages, but also to the

making of reductions. Since area is the

governing factor alike in first and running costs, the cost levels are highly sensitive to reductions in size. in this respect, blue lines prints or Van Dykes positives from paper negatives yield productions at costs just as elastic as those encountered in photo-offset and analyzed in

the preceding chapter. That is to say, a

reduction of approximately 30% in the size

of the page will reduce costs by 50%. The

6” x 9” page would have to be reduced to

something like 4” x 6”; the 8½” x 11”

page to something like 5½” x 8½”, to

effect this reduction in cost.

Dyke positive, B-W, and Ozalid) are incapable of enlarging copy or reducing it, and

equally incapable of dealing with such a

thing as a book with pages printed on both

sides. Those that involve the use of the

photostat are adapted not only to the reproduction of book pages, but also to the

making of reductions. Since area is the

governing factor alike in first and running costs, the cost levels are highly sensitive to reductions in size. in this respect, blue lines prints or Van Dykes positives from paper negatives yield productions at costs just as elastic as those encountered in photo-offset and analyzed in

the preceding chapter. That is to say, a

reduction of approximately 30% in the size

of the page will reduce costs by 50%. The

6” x 9” page would have to be reduced to

something like 4” x 6”; the 8½” x 11”

page to something like 5½” x 8½”, to

effect this reduction in cost.

In respect of size of edition, the zones in the neighborhood of five copies, and again in the neighborhood of twenty-five copies, show themselves as the most sensitive. They are the meeting points of the different techniques. Carbon copying, Ozalid, and B-W copying come very close together at the fifth copy; photo-offset, photostat, and Van Dyke positives meet each other close to the twenty-five mark.

The key figures for the cost of reproduction (full size) are on page 79.

Photostat and photo-offset cross each other in the reproduction of the octavo book at the twenty-five copy line. the reproduction of the typescript page they meet at a smaller edition—thirteen copies. That is to say, in an edition of thirteen copies the photo-offset of an 8½” x 11” page will cost the same as the photostat, and there will be eighty-seven extra photo-offset copies, the cost of which has been absorbed in the edition of thirteen.

Why is there this difference? Chiefly because the negatives in the dimension 6” x 9” can be laid on the frame for photostating in a very economical way, and eight pages can be copied at a time.

Another fact must be noted: the

photostat and blueprint techniques are all

elastic in that additional copies can be

run at constant cost, once the first costs

are assumed. With the photo-offset ∣

p.78

∣

p.78

∣

p.79

technique, the full edition must be made

at one running.

p.79

technique, the full edition must be made

at one running.

TABLE XXIX

TABLE XXX

KEY FIGURES OF UNIT COSTS OF REPRODUCTION

| One Copy of 100,000 Words, Unit Cost | ||

| Typescript | $40.00 | (from either book or typescript) |

| Photostat negative | 37.50 | (from book only) |

| Ozalid or B-W | 10.85 | (from typescript only) |

| Five Copies, Unit Cost | ||

| Typescript and carbons | $12.16 | (from 6” x 9” book or typescript) |

| *Blue line print from paper negative | 15.95 | (from book only) |

| Ozalid or B-W | 10.85 | (from typescript only) |

| Twenty-five Copies, Unit Cost | ||

| Photostat | $13.46 | (from 6” x 9” book or typescript) |

| Photo-offset | 13.72 | ” “ “ “ “ |

| Van Dyke positive from paper negative | 11.65 | ” “ “ “ “ |

| Blue line print from paper negative | 6.95 | ” “ “ “ “ |

| Blue line print from Van Dyke negative | 11.55 | ” “ “ “ “ |

| Ozalid or B-W | 10.85 | ” “ “ “ “ |

| Photo-offset | 26.72 | ” “ “ “ “ |

| Photostat | 50.10 | ” “ “ “ “ |

The foregoing discussion has dealt

with printed and typescript texts. It is

important, however, to take into account

the fact that all the blueprint, photo-∥

offset, and photostat processes will reproduce charts, figures, and line drawings

as easily as texts. This aspect of the

problem of reproducing research materials

will receive more complete analysis in the

next chapter.

offset, and photostat processes will reproduce charts, figures, and line drawings

as easily as texts. This aspect of the

problem of reproducing research materials

will receive more complete analysis in the

next chapter.